Pharmaceutical Packaging Equipment Market Overview

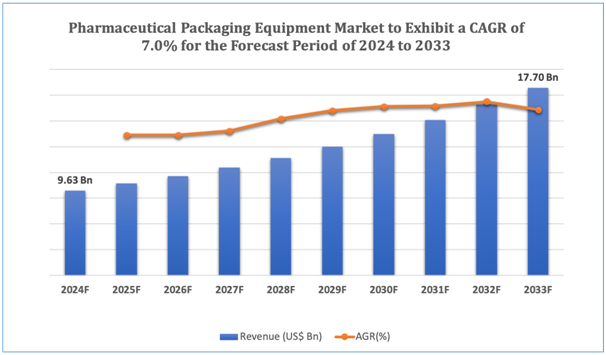

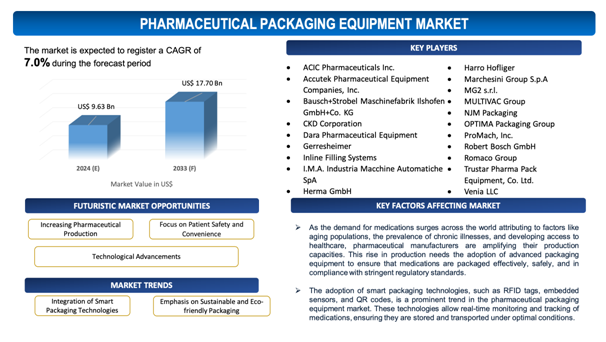

The global pharmaceutical packaging equipment market is estimated to be worth over USD 17.70Bn in 2033 and is expected to grow at CAGR of7.0% during the forecast period (2024-2033).

Pharmaceutical packaging equipment is transforming the healthcare panorama by ensuring the efficient, safe, and reliable delivery of medications. These complex machines are designed to handle various packaging formats, comprisingvials,blister packs, ampoules, and bottles, all while adhering with stringent regulatory standards. The incorporation of advanced technologies such as automation, robotics, and advanced monitoring systems into packaging equipment has considerablyimproved production consistency and efficiency, substantiallymitigating human error and operational costs. Automated systems are capable of performing high-speed tasks like filling, sealing, labeling, and inspecting, which simplifies the production process.

In addition, the incorporation of serialization and traceability features into packaging machinery is essential for combating counterfeiting and ensuring the authenticity of pharmaceutical products throughout the supply chain. This is essentiallyprominent in a global market with a growing demand for medications. Advanced packaging solutions, such as smart packaging with embedded sensors, are also emerging, offering real-time data on the condition and usage of drugs. This is especially beneficial for temperature-sensitive biologics and personalized medicines, ensuring they remain effective until they reach the patient.

Sustainability is another crucial focus area, with novel packaging equipment being intended to accommodate environment-friendly materials and minimize waste. This transition towards more sustainable practices is not only environmentally beneficial but also aligns with growing consumer and regulatory demands for greener solutions.

Overall, pharmaceutical packaging equipment is improving the safety, efficiency, and reliability of drug delivery. By minimizing errors, ensuring compliance, and enhancing the traceability and condition of medications, these developments are essential for patient safety and public health. As the technology continues to flourish, it is set to further revolutionize the healthcare outlook, making medications more safer and accessible for patients globally.

Figure 1. Pharmaceutical Packaging Equipment: Market Size

Get more details on this report - Request Free Sample

Key Market Insights

The global pharmaceutical packaging equipment market is witnessingstrong growth, fuelled by growing demand for progressive drug delivery systems and stringent regulatory requirements. Latest market insights exhibit that automation and technological innovations are crucial in defining the industry. Automation improves production efficiency and minimizes human error, resulting intoincreased output and consistent product quality. The market is experiencingnotable developments in serialization and traceability technologies, essential for conflicting counterfeiting and ensuring the authenticity of medications.

Novel technologies such as smart packaging, integrating sensors for real-time monitoring of drug conditions, are gaining momentum, particularly for temperature-sensitive biologics and personalized medicines. Sustainability is also a major trend, with equipment being developed to support environment-friendly packaging materials and minimize waste, in line with global environmental goals. Major players are investing heavily in R&D to innovate and incorporate IoT and AI into packaging processes, improving predictive maintenance and operational efficiency. The Asia-Pacific region is emerging as a significant market owing to the growing pharmaceutical manufacturing activities and favourable government initiatives.

Additionally, the COVID-19 pandemic has propelled the adoption of advanced packaging solutions to meet the pressing demand for vaccines and treatments, underscoring the crucial role of reliable packaging in ensuring the efficient and safe distribution of pharmaceutical products. All in all, the market is marked by swift technological developments, an emphasis on sustainability, and growing investments in R&D, placing it for sustained growth and transformation in the healthcare industry.

Market Dynamics

Market Drivers

Increasing Pharmaceutical Production

The increasing pharmaceutical production one of the primary factors for the growth of the global pharmaceutical packaging equipment market. As the demand for medications surgesacross the worldattributing to factors like aging populations, the prevalence of chronic illnesses, and developing access to healthcare, pharmaceutical manufacturers are amplifying their production capacities. This rise in production needs the adoption of advanced packaging equipment to ensure that medications are packaged effectively, safely, and in compliance with stringent regulatory standards. Modern packaging equipment, with its automation and high-speed capabilities, acknowledges the need for increased throughput, reducing impasses in the production process and ensuring timely delivery of pharmaceuticals to the market.

Moreover, the diversity and intricacy of pharmaceutical products, including biologics, injectables, and personalized medicines, require sophisticated packaging solutions that can handle different formats and ensure the integrity of sensitive products. Advanced packaging technologies, such as blister packaging machines, vial filling and sealing equipment, and serialization systems, are crucial for sustaining product quality and traceability throughout the supply chain. The growth in pharmaceutical production also drives investments in R&D for advanced packaging solutions, such as smart packaging with embedded sensors for real-time monitoring, which further accelerates market growth.

Furthermore, the expansion of the pharmaceutical industry in emerging markets, supported by favourable government policies and increasing healthcare spending, contributes to the demand for modern packaging equipment. As pharmaceutical companies strive to meet global demand and maintain competitive advantage, the adoption of leading-edge packaging equipment becomes essential, fueling the overall growth of the pharmaceutical packaging equipment market.

Market Restraints

With regard to numerous advantages of pharmaceutical packaging equipment, the market faces several challenges due to the unique characteristics and requirements associated with these potent pharmaceutical products. Some of the key market challenges include:

- High Initial Investment and Maintenance Costs: The adoption of progressive pharmaceutical packaging equipment includessubstantial initial capital expenditure, involving the cost of purchasing and installing sophisticated machinery. In addition, continuous maintenance and the necessity for skilled technicians to operate and repair these machines can further elevates costs. These financial barriers can be especiallydifficult for small and medium-sized pharmaceutical companies, restricting their ability to invest in and adopt state-of-the-art packaging technologies.

- Stringent Regulatory Compliance: The pharmaceutical packaging industry is subject to stringent regulatory standards and compliance requirements set by authorities such as the EMA, FDA, and other global regulatory bodies. Ensuring compliance with these regulations often needsongoing updates and modifications to packaging equipment, which can be time-consuming and costly. Non-compliance can result inmajor penalties and product recalls, posing a significant risk to manufacturers. These stringent regulatory demands can hinder investments and decelerate the adoption of new packaging technologies, thuslimiting market growth.

Get more details on this report - Request Free Sample

Market Opportunity

Focus on Patient Safety and Convenience

The growing emphasis on patient safety and convenience stands as a substantial market opportunity for the growth of the global pharmaceutical packaging equipment market. Since the healthcare industry progressively prioritizes patient-centric approaches, there is a soaring demand for packaging solutions that improve medication efficacy, safety, and ease of use. Cutting-edge packaging technologies, such as child-resistant and tamper-evident packaging, ensure that medications are secure and minimize the risk of accidental ingestion or tampering, directly acknowledging patient safety concerns. In addition, advances in smart packaging, comprising features like embedded sensors and RFID tags, offer real-time monitoring of drug conditions, ensuring that medications are stored and transported under optimal conditions, which is essential for maintaining drug efficacy.

Convenience-focused packaging solutions, such as easy-to-open blister packs and pre-filled syringes, enhance patient adherence to medication regimens by facilitating the administration process. This is especiallyprominent for elderly patients and those with disabilities, who are likely to struggle with conventional packaging. User-friendly packaging designs that integrate clear labelling and dosage instructions also assist in minimizing medication errors, further improving patient safety.

As pharmaceutical companies determine the value of patient-centric packaging, they are more and more investing in advanced packaging equipment that can offer these innovative solutions. This transition not only fulfils regulatory and consumer demands but also offers a competitive edge in the market. Furthermore, the surging trend towards personalized medicine needs flexible packaging solutions that can cater to individual patient needs, fuelling the demand for versatile and adaptive packaging equipment. All in all, the focus on patient safety and convenience is boosting technological developments and investments in the pharmaceutical packaging equipment market, creating significant growth opportunities.Top of Form

Bottom of Form

Market Trends

- Integration of Smart Packaging Technologies: The adoption of smart packaging technologies, such as RFID tags, embedded sensors, and QR codes, is a prominent trend in the pharmaceutical packaging equipment market. These technologies allow real-time monitoring and tracking of medications, ensuring they are stored and transported under optimal conditions. Smart packaging also improves patient engagement and compliance by offering interactive features like usage instructions,digital reminders, and authentication tools. This trend is fuelled by the growing demand for personalized medicine and the necessity for enhanced drug efficacyand safety.

- Emphasis on Sustainable and Eco-Friendly Packaging: There is a soaring focus on sustainability in the pharmaceutical packaging industry, fuelled by regulatory pressures and consumer demandfor environmentally friendly solutions. Manufacturers are investing in packaging equipment that facilitates the use of biodegradable, recyclable, and compostable materials. In addition, advancements in packaging design focusonreducing waste and minimize the carbon footprint. This trend not only streamlines with global environmental goals but also fulfils the sustainability standards set by regulatory bodies, placing companies as responsible and forward-thinking in the perception of stakeholdersand consumers.

Pharmaceutical Packaging Equipment Market: Key Segments

By Product

- Primary Packaging Equipment

- Secondary Packaging Equipment

- Labelling and Serialization Equipment

By Formulation

- Liquid Packaging Equipment

- Solid Packaging Equipment

- Semi-Solid Packaging Equipment

- Other Product Packaging Equipment

By Automation

- Automation

- Semi-Automation

- Manual

By End User

- Pharmaceutical Contract Manufacturing Companies

- Pharmaceutical Manufacturing Companies

By Key Geographical Regions

- North America

- Europe

- Asia-Pacific

- Middle East and Africa

- South America

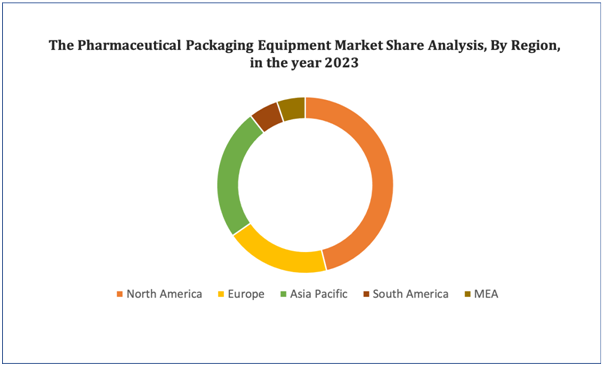

Figure 4. Pharmaceutical Packaging Equipment Market: Distribution by Region

Get more details on this report - Request Free Sample

Pharmaceutical Packaging Equipment Market: Regional Analysis

Asia-Pacific is estimated to dominate the market attributing to the growing demand for pharmaceutical packaging equipment in the region. The Asia-Pacific region's leadership in the pharmaceutical packaging equipment market is underpinned by numerous factors, comprising stringent government regulations and policies aimed at combating counterfeit products.

Europe is estimated to be the fastest growing region owing to the region's robust production of pharmaceutical products. The European pharmaceutical sector is renowned for its modern manufacturing capabilities and stringent quality standards, making it a leading contributor to the region's economic growth.

Leading Pharmaceutical Packaging Equipment Developers

Industry Trends and Global Forecasts, 2023-2035 report features an extensive study of the current market landscape, market size and future opportunities associated with the Pharmaceutical Packaging Equipmentmarket, during the given forecast period. Further, the market report highlights the efforts of several stakeholders engaged in this rapidly emerging segment of the biopharmaceutical industry. Key takeaways of the Pharmaceutical Packaging Equipmentmarket are briefly discussed below.

The report includes the list of players operating in the global Pharmaceutical Packaging Equipment market. Some of the key players include:

- ACIC Pharmaceuticals Inc.

- Accutek Pharmaceutical Equipment Companies, Inc.

- Bausch+Strobel Maschinefabrik Ilshofen GmbH+Co. KG

- CKD Corporation

- Dara Pharmaceutical Equipment

- Gerresheimer

- Inline Filling Systems

- I.M.A. Industria Macchine Automatiche SpA

- Herma GmbH

- Harro Hofliger

- Marchesini Group S.p.A

- MG2 s.r.l.

- MULTIVAC Group

- NJM Packaging

- OPTIMA Packaging Group

- ProMach, Inc.

- Robert Bosch GmbH

- Romaco Group

- Trustar Pharma Pack Equipment, Co. Ltd.

- Venia LLC

Pharmaceutical Packaging Equipment Market: Key Developments

- In October 2023, Stoelzle Pharma, one of the world’s leading manufacturer of top-tier primary packaging glass, introduced their brand-new PharmaCos Line. Notably, this new line is manufactured in a pharmaceutical-grade environment, adhering to the rigorous standards set by the pharmaceutical industry. All Stoelzle Pharma production sites are Pharma certified, ensuring the highest quality and compliance with industry regulations.

Scope of the Report

The market report presents an in-depth analysis of the various firms / organizations that are engaged in this market, across different segments, as defined in the below table:

|

|

Key Report Attributes |

Details |

||

|

|

Base Year |

2023 |

||

|

|

Forecast Period |

2024-2033 |

||

|

|

CAGR (2024-2033) |

7.0 % |

||

|

|

Product |

|

||

|

|

Formulation |

|

||

|

|

Automation |

|

||

|

|

End User |

|

||

|

|

Key Geographical Regions |

|

||

|

Key Companies Profiled |

|

|

||